|

|

|

|

|

|

|

|

Technology |

Bailey Tool Institutes Operational Equipment

|

OEE = Availability x Performance x Quality |

Using Six-Sigma Project Methodology

We started this project by using the Six Sigma methodology DMAIC: 1) Define; 2) Measure; 3) Analyze; 4) Improve; and 5) Control.

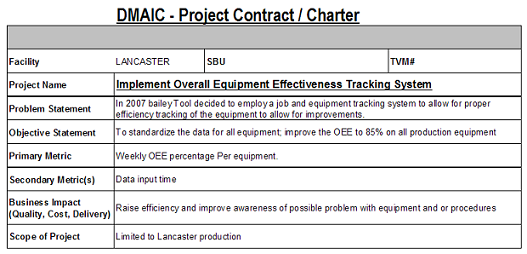

I. Define Phase

The project definition was established using the project charter shown below:

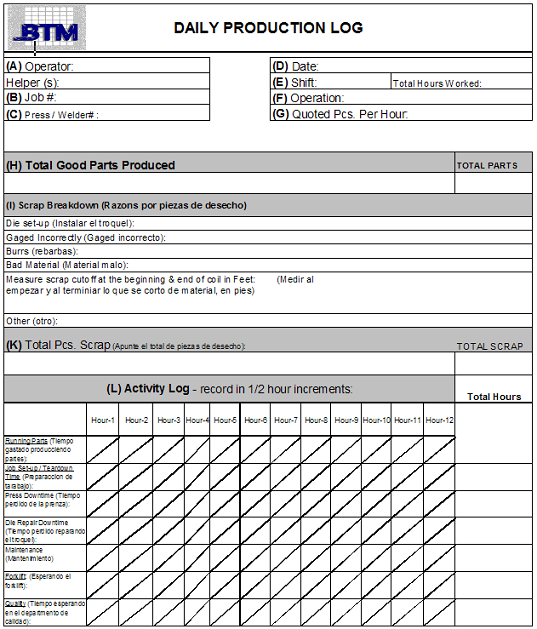

II. Measure Phase

The measure phase began with adapting the Daily Production Log (DPL) to accommodate the data needed to track the OEE. This form is used by each operator on every piece of equipment to track all hours, down time and production.

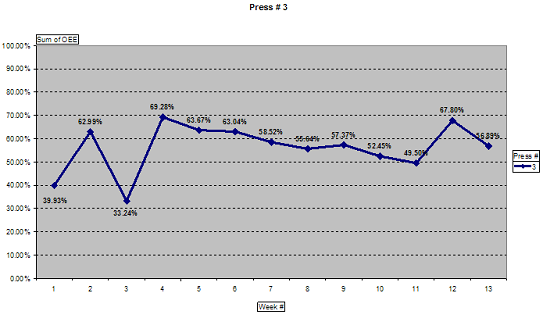

III. Analyze Phase

The collected data is analyzed and the results are posted in the appropriate departments in the form of a line graph as shown below:

IV. Improve Phase

A team meeting is called to discuss the OEE for the equipment. Six Sigma tools such as YX diagrams fish bone diagrams to identify potential causes for low OEE. The potential causes are addressed with the appropriate tools such as 5S, a Kaizen event or employing Advanced Statistical Analysis

V. Control Phase

In the control phase data is continuously monitored to ensure that all control parameters are within desired ranges.

Copyright © 2008 Bailey Tool & Manufacturing | Site by Visual App