|

|

|

|

|

|

|

|

Technology |

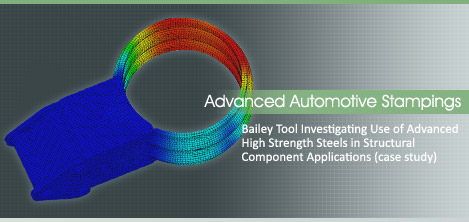

Materials ScienceBailey Tool Investigating Use of Advanced High Strength Steels in Structural Component ApplicationsKey IssuesAutomotive designers face a three-fold problem. Government regulations require that cars be safer; this increases the car weight. They also require improved fleet mileage. Most improvements for engine efficiency and aerodynamics are already being used, so the main area left is weight reduction. This leads to the third problem, that most of the public doesn't want to buy Rabbits. The question then becomes, how do you make the car lighter? Significant gains have been made using HSLA grades, but these grades have limited formability, especially in the higher strength grades. Several types of steel have been developed to fill these needs, known collectively as Advanced High Strength Steels (AHSS). They offer significantly higher strength with reasonable forming, which can allow significant thickness reduction without loss of part strength. AHSS MaterialsSome of these steels, such as Dual Phase steel, have been available since the early 1980's, but until recently there has been little interest in their use. The principal problem was cost, which is significantly higher than comparable HSLA grades. The material also has different strain-hardening behavior compared to other types of steel, so die designs are different from standard practices. The need to reduce weight to meet the new standards makes it worthwhile to look at their use. The main AHSS applications are for frame and crash structures, since they either allow for significant weigh reduction or reduced product liability to justify their costs.

Application of AHSS to Interior Structural Components

Limited work has been done on interior structural components with AHSS, and Bailey Tool saw the potential for advancing these grades for ride control and NVH components because of the functional requirements. Components tend to be heavy and require good fatigue resistance, leaving opportunities for weight savings with application of AHSS grades. Bailey Tool is working closely with one of our Tier 1 customers on evaluating applicability of AHSS grades in a fluid filled rubber steel encapsulated vibration isolation mount application. The component shell has three stampings made from HSLA 50 material 3mm thick as shown below. Several issues are investigated in this study: 1) Would it be possible to make the 7 stage drawn and trimmed can from AHSS material; 2) Would welding AHSS can to legs made from HSLA pose issues; 3) Are there opportunities for weight savings through use of thinner material and/or redesign of the two larger legs. FEA analysis predicts that simpler legs might be sufficient from a static loading standpoint with maximum Von Mises stress less than 70% of material yield strength.

Status of ProjectWe have successfully drawn several cans from DP600 advanced high strength material. We are currently making some prototype simpler legs from AHSS and expect to be sending some prototype assemblies to our customer for durability testing shortly.

|

Copyright © 2008 Bailey Tool & Manufacturing | Site by Visual App